If your home was built in or around 1970 to 1974, there is a chance it may have been built with aluminum (Aluminium if you are from the UK) electrical wiring. If your home is wired with aluminum, it has probably had a retrofit by now, no longer has electricity, or has already burned down. In our case there are some circuits that were either skipped or poorly done in the original retrofit and they have caused a few spooky and frightening events.

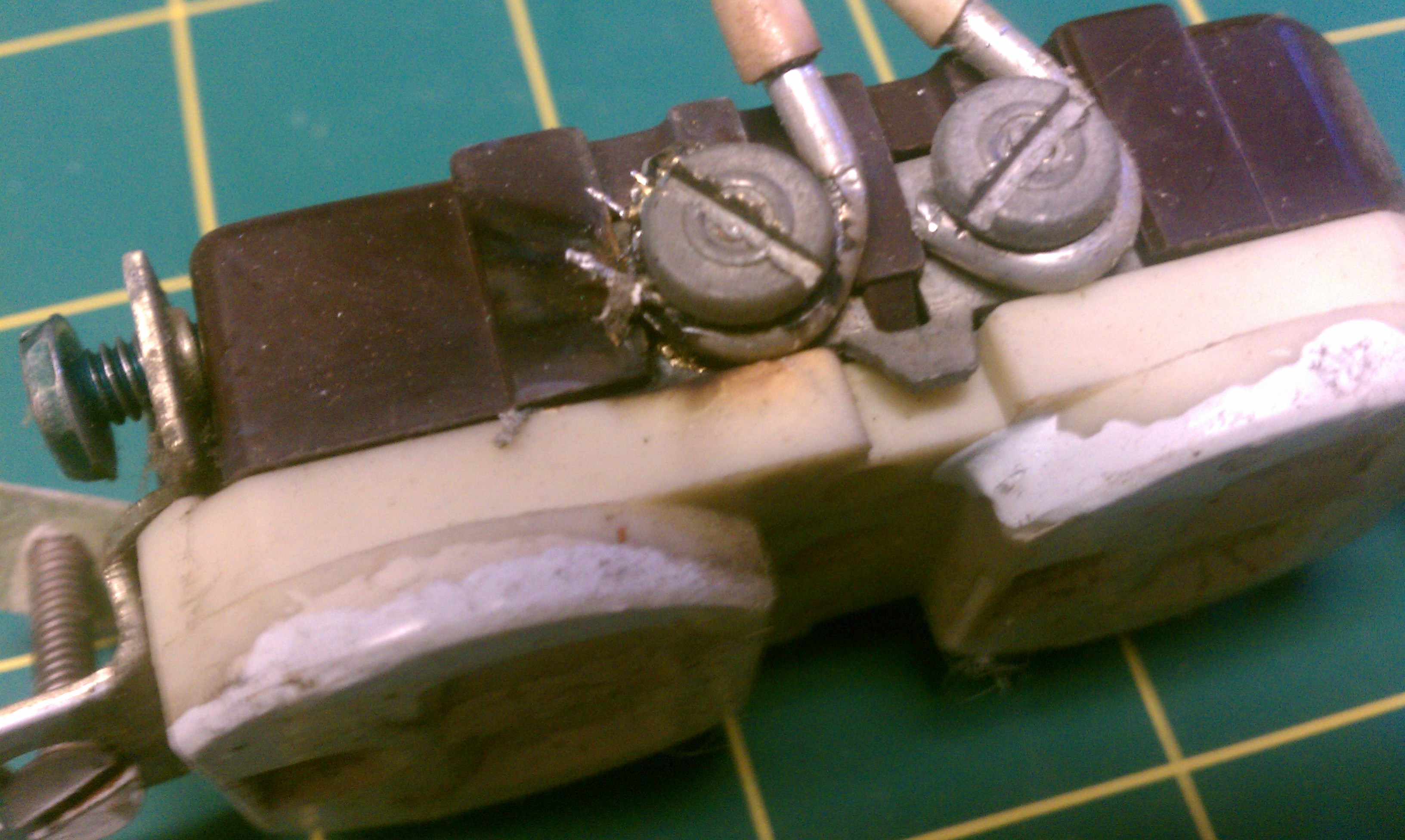

Our house was built in 1970 and was “allegedly” retrofitted under warranty sometime before 1984 when last sold. The procedure was to verify that all exposed connections were at least covered in a dielectric grease to prevent oxidation. A better method is to extend all aluminum wire ends with copper pigtails using wire nuts filled with the dielectric grease. That’s what I do when I find one of these hazardous connections. In the image above, the source side neutral wire shows some extreme arcing evidence with the built up fingers and charring of the wire and outlet body plastic. This convenience outlet was only used to power a night light, but a downstream outlet in the same circuit is used more extensively. The downstream outlet lost power first. An inspection of that outlet did not reveal the source, neither did the subsequent inspection of the circuit breaker (although it appeared to be well past it’s maximum useful life, see image below). The search then led to this outlet.

How does this happen? Well, all metals oxidize when exposed to air. Aluminum oxide is white or nearly transparent but more importantly it is non conductive. As the aluminum wire oxidizes under the terminal screw. It begins to develop a resistance at the connection. The now resistive junction generates heat (and a small voltage drop). Heating softens the wire. The softened wire can stretch under the mechanical stress of lateral tension and/or the pressure of the terminal screw. As the wire stretches, it becomes thinner. As the wire becomes thinner, it becomes loose. Once the connection is loose enough, it will begin arcing when current flows through. Once it begins arcing, the entire process accelerates. In summary: Aluminum wiring should never have been allowed!